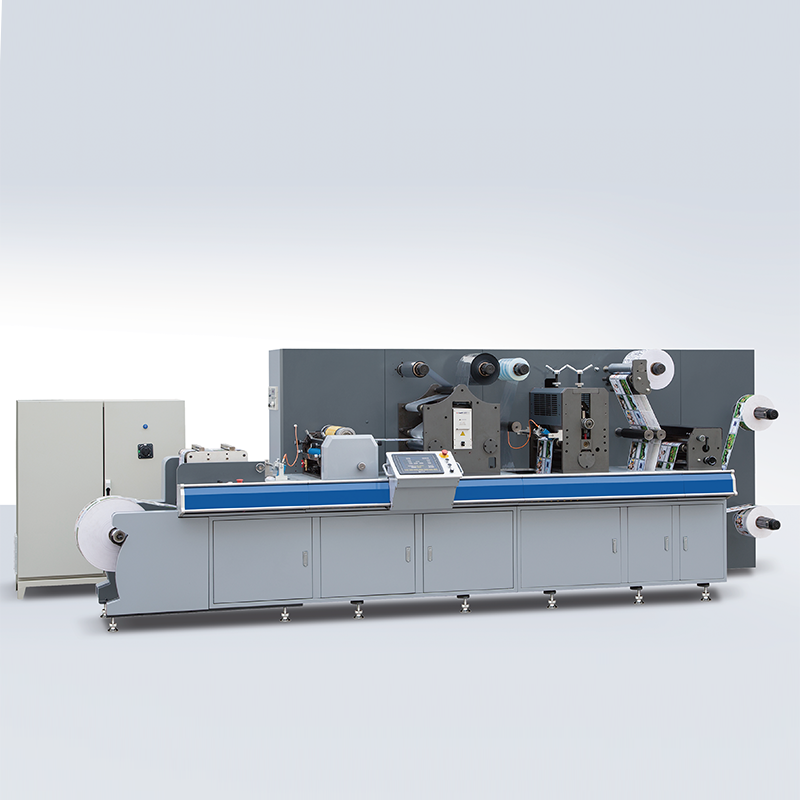

Stack Flexo Press with Three Die-cutting Stations ZBS-320G/450G

1.Adopts the ceramic anilox cylinder to transfer the ink.

2.Each printing unit adopts 360°plate-adjustment.

3.Three die-cutting stations, the first and second die-cutting station can do double side work, the third die-cutting station can be used as sheeter.

online service

1.Adopts the ceramic anilox cylinder to transfer the ink.

2.Each printing unit adopts 360°plate-adjustment.

3.Three die-cutting stations, the first and second die-cutting station can do double side work, the third die-cutting station can be used as sheeter.

4.Computerized web-guiding system is installed in the front of the printing unit, ensuring the materials are in the right position. (standard configuration)

5.After sheeting in the third die-cutting station, conveyor belt can output the products orderly. (optional)

6.Unwinding and rewinding tension are auto-controlled by magnetic powder, two rewinders is optional in this machine.

7.Video inspecting system is an option, it can supervise the printing quality when in high speed.

8.The ink rollers can be separated from the printing roller, and keep running when the machine stops.

9.Main motor use inverter to adjust stepless speed.

10.The machine can finish material-feeding, printing, varnishing, drying, laminating, die-cutting, rewinding sheeter in one process. It is an ideal machine for printing adhesive labels.

Main Technical parameters

|

Model

|

ZBS - 320G

|

ZBS - 450G

|

|

Printing speed

|

60 米 / 分 (m/min)

|

60 米 / 分 (m/min)

|

|

Printing colour

|

1 - 6 色 (4 + 4 色)(colours)

|

1 - 6 色 (4 + 4 色)(colours)

|

|

Max. web width

|

320mm

|

460mm

|

|

Max. printing width

|

310mm

|

450mm

|

|

Max. unwinding diameter

|

650mm

|

650mm

|

|

Max. rewinding diameter

|

650mm

|

650mm

|

|

Printing length

|

177.8 - 355.6mm 206.3 - 460.3mm (选配 Options) 238.1 - 539.25mm (选配 Options)

|

177.8 - 355.6mm 206.3 - 460.3mm (选配 Options) 238.1 - 539.25mm (选配 Options)

|

|

Registration Accuracy

|

±0.1mm

|

±0.1mm

|

|

Dimensions(L×W×H)

|

260011003050mm (6 色)

|

260012303050mm (6 色)

|

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

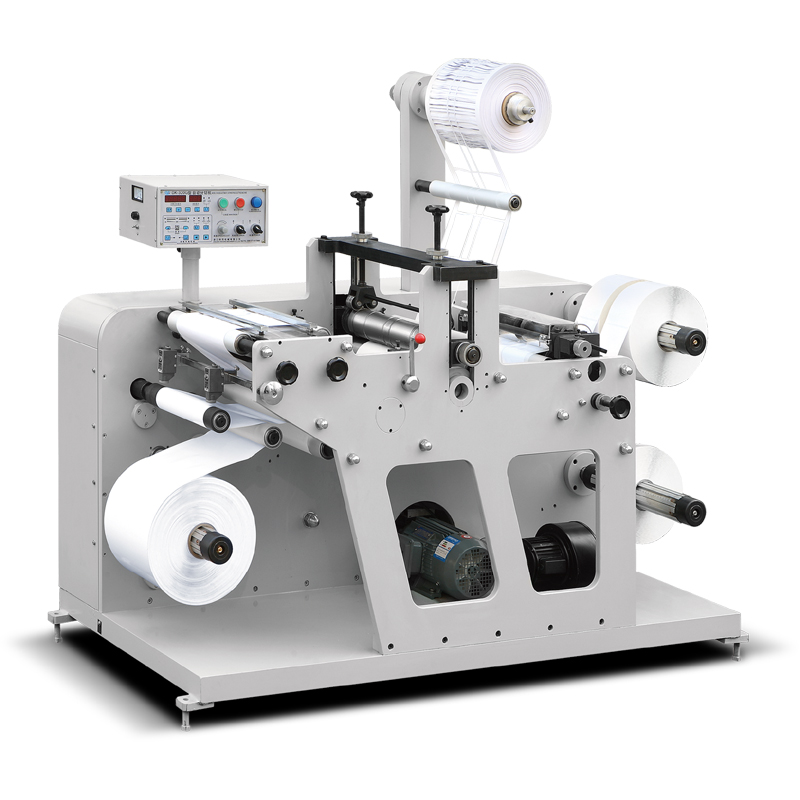

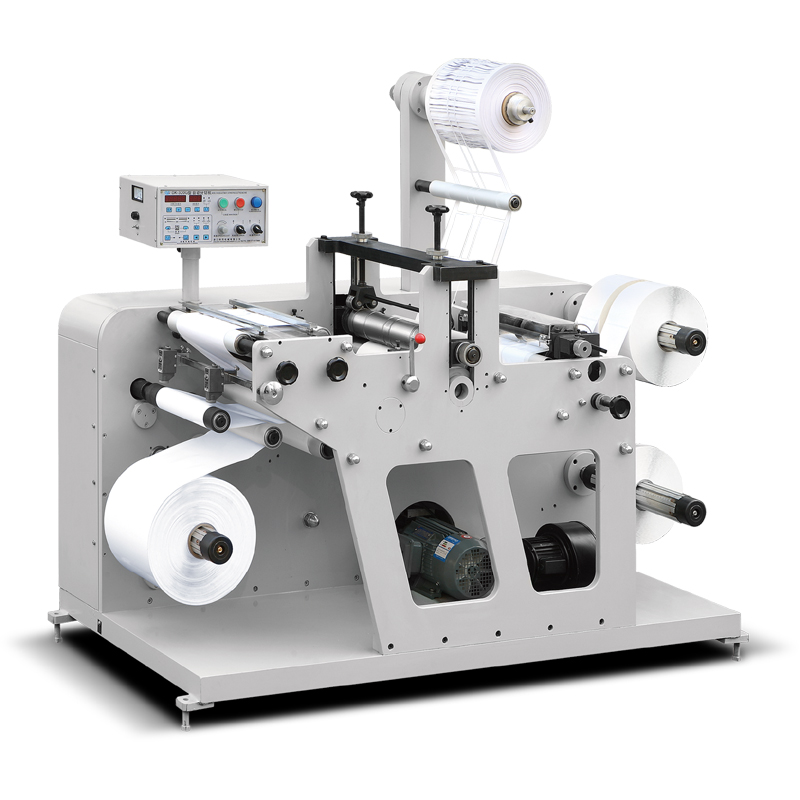

Rotarysemi-rotary Label Die-cutting Machine ZM-320

ZM-320 rotary/semi-rotary label die-cutting machine is new developed converting machine equipped with inline slitter.This machine adopts latest Rexrtoh-Bosch (Germany) servo motors and control system, including: unwinder, web-guider, lamination, register die-cutter, slitter and dual rewinder. The register die-cutting system is our patented product. It can be full rotary or semi-rotary die-cutter according to the production requirement.

Learn MoreStack Flexo Press with Three Die-cutting Stations ZBS-320G/450G

1.Adopts the ceramic anilox cylinder to transfer the ink.

2.Each printing unit adopts 360°plate-adjustment.

3.Three die-cutting stations, the first and second die-cutting station can do double side work, the third die-cutting station can be used as sheeter.

Rotary/Semi-rotary Label Die-cutting Machine ZM-320

ZM-320 rotary/semi-rotary label die-cutting machine is a converting machine equipped with inline slitter. This machine adopts latest Rexrtoh-Bosch (Germany) servo motors and control system, including: unwinder, web-guider, lamination, register die-cutter, slitter and dual rewinder.

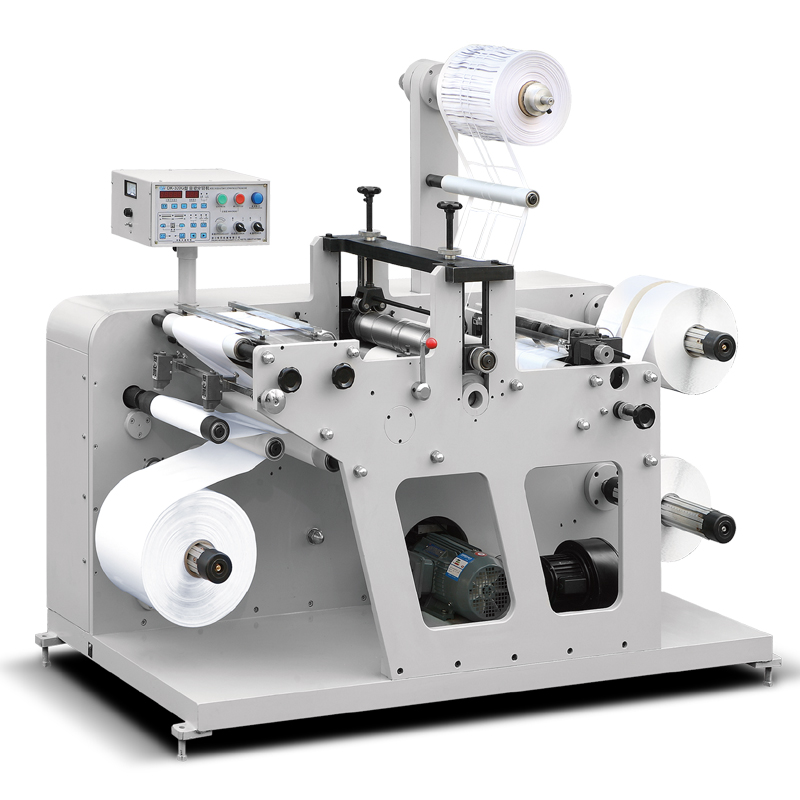

Learn MoreSlitting Machine with Rotary Die-cutting Station DK-320G/450G

DK-320G Slitting machine with rotary die-cutting function is upgraded from DK-320 slitting machine, it is equipped with high accuracy rotary die-cutting system. This machine is suitable for blank adhesive labels. Die-cutting, laminating (optional), slitting can be finished in one process. It has the function of automatic meter counting, automatic stop and web guiding by photocell. The machine has the characteristic of compact structure, fast speed, high efficiency, easy operation, accurate slitting and steady running etc.

Learn More